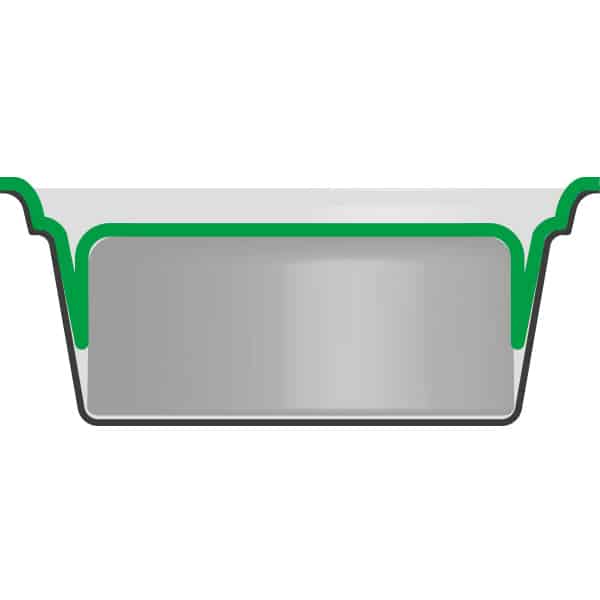

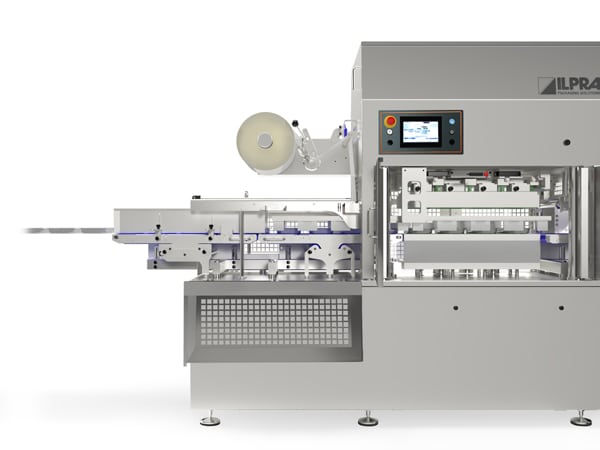

- In Line

This machine is an effective in-line model that can simultaneously process three 187×137mm containers. Its flexibility is suited to a wide range of packaging applications, such as fruit, meat, ready meals, and fish.

The FoodPack 1450 is a high-performance, automatic in-line tray sealer, representing the ideal mix of dependability and flexibility for companies looking to enhance their packaging processes. Its design ensures seamless integration into current production setups, accommodating a broad spectrum of products thanks to its large sealing area and straightforward operation.

-

-

-

-

-

-

-

-

| Technical | FoodPack 1450 | ||

| Dimensions | 331 x 90 x h 190 cm | ||

| Weight | circa 1500 Kg | ||

| Air Consumption | 6 bar - 5 Nlt/cycle | ||

| Sealing Area | 560 x 350 x h 120 mm |

CPS technology

his cutting-edge technology guarantees a continuous flow of trays into the machine, making the conveyor belt adept at separating and guiding trays straight into the sealing mold without breaks. This efficiency comes from the intricate synchronicity of the jaws and conveyor belts, significantly improving the machine’s operational speed and capacity.

Constant Torque Servo Drive Motors

The unwinding and rewinding system is precisely managed using two sophisticated brushless motors. The initial motor carefully dispenses the film following the control panel’s instructions, while the second motor adjusts to keep the film tension ideal, responding to changes in the waste reel’s size. This arrangement ensures exact film management and movement, handling both neutral and printed films with high accuracy.

Anti-Crush System

A built-in photocell keeps an eye on the tray alignment, triggering an alarm to stop the sealing action if it spots a tray out of place. This precaution helps avoid tray damage, maintains the packaging process’s integrity, and prevents workflow interruptions.

Jaws Carriage

The complete container transportation system is driven by advanced brushless motors, providing accurate control over the opening and closing of the jaws. This control can be fine-tuned through the control panel for specific needs. The carriage is designed with sturdiness in mind, minimizing jaw vibration and thus increasing the precision and speed of container placement.

| E-MEC TECHNOLOGIE Gebaseerd op de volledig elektromechanische beweging van het werkstation, maakt deze technologie een hogere snelheid en productiviteit mogelijk. |

| PROGAS SYSTEEM Technologie gepatenteerd door ILPRA die een lager gasverbruik en een hogere werksnelheid garandeert. Beschikbaar op alle modellen in deze lijn. |

| CONSTANT PLACEMENT SYSTEM This sophisticated system ensures a steady tray supply into the machine, thanks to belt and jaw interpolation, which significantly raises production speed. |

| EXTRASKIN SYSTEM Het maakt Skin packaging mogelijk, zelfs bij hoge uitsteeksels. |

| Optioneel: VOORVERWARMINGSSYSTEEM Voorverwarming van de folie om de verpakking in Skin te optimaliseren. |

| PREDICTIVE Predictief onderhoudssysteem dat de planning van de revisie en vervanging van |

| ID CONTROL SYSTEM Herkenning van bevoegd personeel door badge. Tot drie identificatieniveaus. |

| Optional: Anti-Crush System Avoids tray damage by stopping the sealing process in case of misalignment, preserving the integrity of the product. |